We source only the best steel coils which ensures the highest quality of steel pipes and tubes.

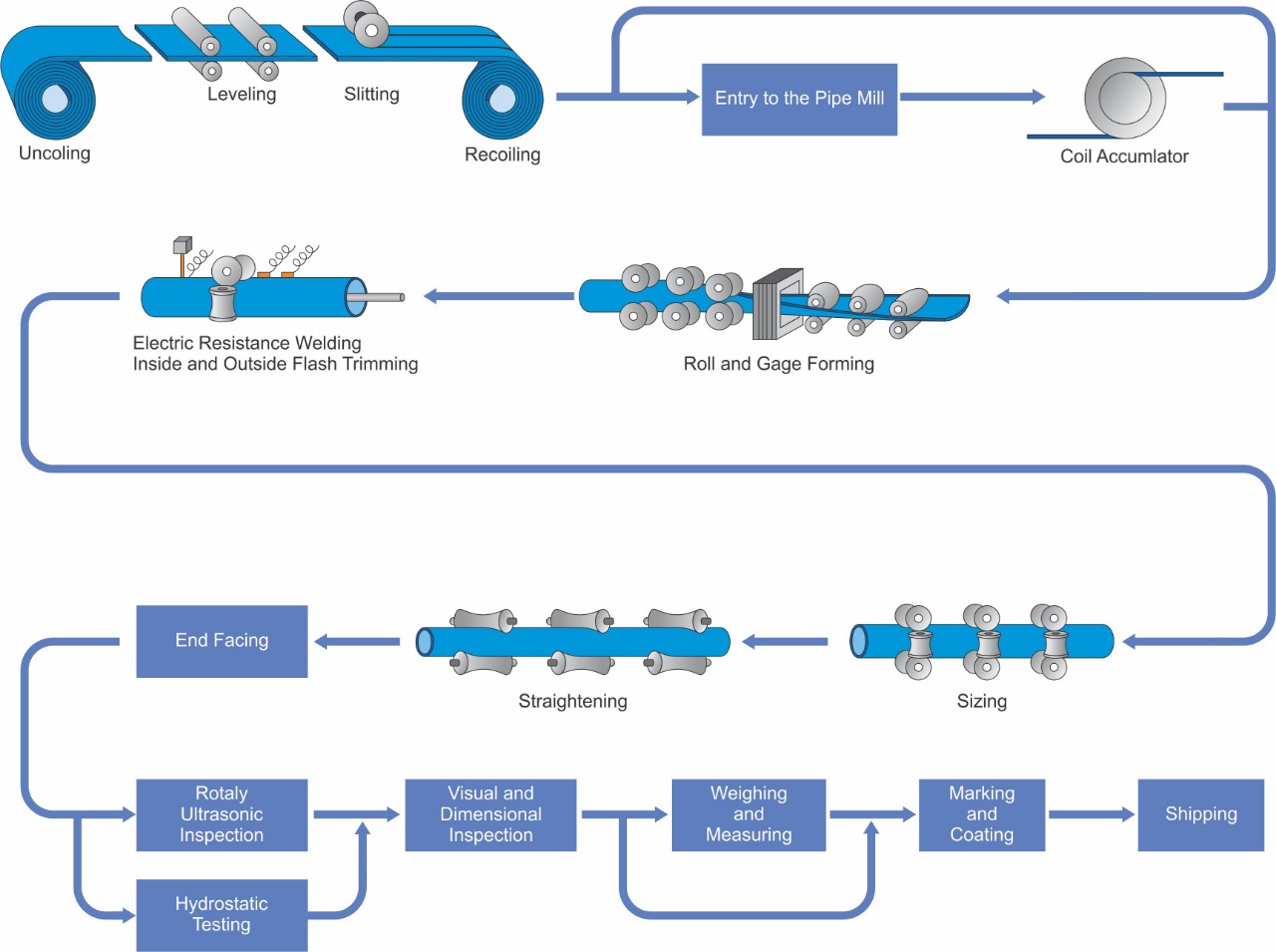

The slitted coil is uncoiled at the entry of ERW mill, this results in a single endless strip.

HR Coils are slitted to pre-determined widths for each and every size of pipes and are recoiled.

With the help of heat and cutting water, the straightened steel coil is curled into a round shape.

With the help of our thermatool welder, the open edges are heated to the forging temperature through high-frequency, low-voltage, high current and press welded by forge rolls making perfect and strong but weld without filler materials.

After water quenching, slight reduction is applied to pipes with sizing rolls. This results in producing desired accurate outside diameter.

At this stage, the pipes are properly straightened providing the right finish to the end product.

This is usually stage, where the pipes ends are faced and bevelled by the end facer.

After all this, various tests and inspections such as rotaly ultrasonic inspection, hydrostatic testing, visual and dimensional inspection, weighing, measuring , marking and coating are done which results in the perfect pipe which is all ready to be shipped.